Solutions for battery testing, measurement and discharging

Our flexible test platforms are designed to adapt as battery technology and your battery testing requirements evolve

Do you want to know more?

Please contact us at info@wireflow.com

WireFlow offers flexible test and measurement systems that cover the entire battery life cycle – from research and development to production, reuse and discharge for recycling. With experience and expertise, software, hardware and support, we are your reliable partner throughout all battery cycles.

Recycling & Repurposing

Bifrost for Recycling and Repurposing provides a safe and efficient way to discharge, classify, and document batteries at the end of their lifecycle. The system evaluates state of health, prepares batteries for safe energy recovery, and identifies cells suitable for reuse. With automated control, monitoring, and reporting, Bifrost ensures safety, traceability, and compliance throughout the recycling and repurposing process.

Customized battery test solution

We can tailor systems to your needs. We have delivered cutting-edge solutions where off-the-shelf products did not suffice, such as cell characterization, rapid BMS prototyping and offline balancing. Together with our innovative products, we create tailored solutions for your battery tests, measurements and discharges.

Research & Development

Reliable testing is essential to ensure battery performance, safety, and durability. With Bifrost for Research and Development, engineers can perform capacity tests, cycle simulations, and measurements to optimize designs.

Flexible, programmable test scenarios enable “what-if” experimentation, while the modular system adapts to any battery chemistry or configuration.

Support Services

Minimize downtime and keep your battery systems performing at their best. Our experts quickly diagnose and resolve issues remotely, while also supporting functional growth to ensure your setup meets evolving operational demands.

Battery Manufacturing

Bifrost for Battery Manufacturing combines charging, configuration, and functional testing in one automated solution. Seamless integration with factory IT systems ensures consistent results, full traceability, and reliable end-of-line performance.

Designed for high-volume production, Bifrost keeps every battery safe, compliant, and ready for shipment or assembly.

After Market & Refurbishment

For safe testing, reconditioning and validation of used battery packs. It evaluates state of health, verifies communication and identifies modules fit for second-life use. The system also supports repairs with new or replacement modules. With configurable tests and automated reporting, Bifrost ensures efficient, traceable refurbishment and consistent safety and performance.

For Engineers–By Engineers.

Battery Test & Measurement Solutions

Our flexible standard systems for battery test and measurement can be adapted to your unique needs

The WireFlow Bifrost Series for battery testing

The WireFlow Bifrost Series is a modular, programmable platform for battery testing and energy management across the entire lifecycle — from research and production to reuse and recycling. Built on the Valand software platform, Bifrost combines precision hardware with powerful scripting and data logging capabilities. Each system can be tailored to specific voltage levels, communication protocols, and test requirements, enabling safe, traceable, and efficient testing at every stage.

By returning discharged energy to the grid or your facility, Bifrost contributes directly to the green transition while reducing operational costs. Designed for flexibility and scalability, the Bifrost Series helps manufacturers and developers ensure performance, safety, and sustainability in every battery application.

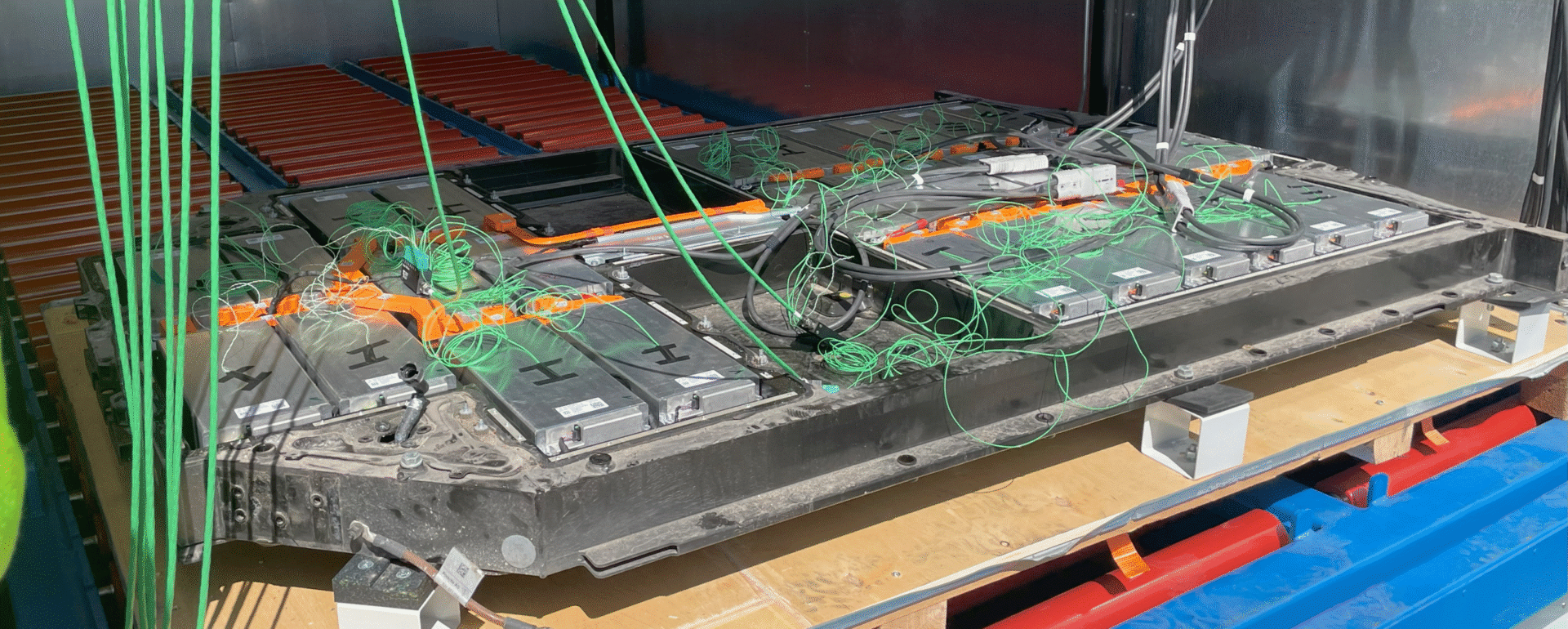

WireFlow VoltDrain for safe battery discharge

A turnkey container solution for safe discharge of electric vehicle batteries in recycling facilities. The system is delivered complete and ready to use, making installation quick and easy. Built-in safety features such as IR camera, automatic shutdown and explosion hatch ensure safe operation.

VoltDrain only requires a standard 230V socket and can be flexibly placed both indoors and outdoors. Thanks to its modular design and quick connectors, it is a cost-effective and user-friendly option for companies that want to manage discharge in a simple and safe way.

Our Clients

Insights

Solutions and Expertise

in Practice

WireFlow Battery Test & Measurement Systems

WireFlow Battery Test & Measurement Systems Presentation

WireFlow solution vertical for battery test and measurement. We provide of the shelf products and turnkey solutions for validation of cells and packs and production test of battery-packs.

WireFlow Battery Cycle Test Rigs

Solution for long term test and qualification of Li-Ion batteries.

WireFlow Bifrost for Module Reuse and Recycling

Hands-on preparation and qualification of EV batteries for repurposing and recycling

WireFlow was one of the selected speakers at the International Congress for Battery Recycling (ICBR) in Basel, Switzerland, September 10-12 September 2024.

Related Case Studies – Battery test & Measurment

Case studies about some of the projects we’ve carried out in the past

Vinga Cycle Rig System

Brompton Bicycle builds one of the most iconic foldable commuter bikes and is Britain’s largest bike producer. Upon introduction of their first electric bike to the market, they needed a top-of-the line battery testing solution. Initially, the requirement was to test three packs, but the solution had to be scalable for easy upgrade to up to ten packs…

Charge and Test System for Li-Ion Battery

Toyota Material Handling Manufacturing Sweden is one of the world’s largest factories for manufacturing of warehouse trucks. Toyota was in progress of introducing a new generation of Li-Ion batteries for their trucks and needed new charging and test stations for the battery manufacturing line.

Battery Cycle Test Rigs, A Solution for long term test and qualification of Li-Ion batteries

Micropower builds modular Li-Ion battery packs and chargers for a wide range of applications such as automotive, utility vehicles and mobile storage solutions.

They needed a safe, reliable and flexible test solution that could cycle battery packs unattended for many months, while logging large amounts of measurement data from the DUT (device under test).

Donsö EV-Battery Reuse and Recycling System

A WireFlow Bifrost Battery Test & Measurement solution for Stena Recycling which is a part of the goal to ensure that batteries can be repurposed, remanufactured, or recycled at the end of their life.