WireFlow Test Framework

Peripheral systems

With WATS I can access data from the manufacturing site directly on my mobile phone.

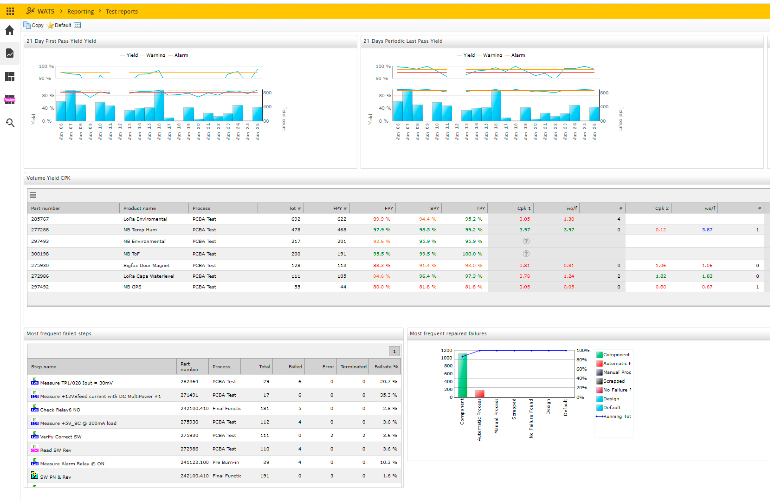

Test report analyzing with the WATS manufacturing dashboard

Test data storage

The test sequence not only indicates pass or fail for each board tested, it also takes measurements of various parts of the boards tested. Test data generated for each tested board is concluded with a pass or fail. If all the test data is stored and archived, it can give valuable insights that can be used to better understand and evolve the existing manufacturing- and test processes and improve product designs. We use the tool WATS from Virinco to help you gain new insights from your manufacturing data. By using WATS, you can quickly identify production yield issues, frequent test or product failures, poor test coverage or other performance problems, in real-time, directly through your web browser or mobile device. We have ready-to-use design patterns for integrating WATS into the WireFlow test framework and our experience is that this test data analytics is both useful and appreciated by our customers.

Label printers

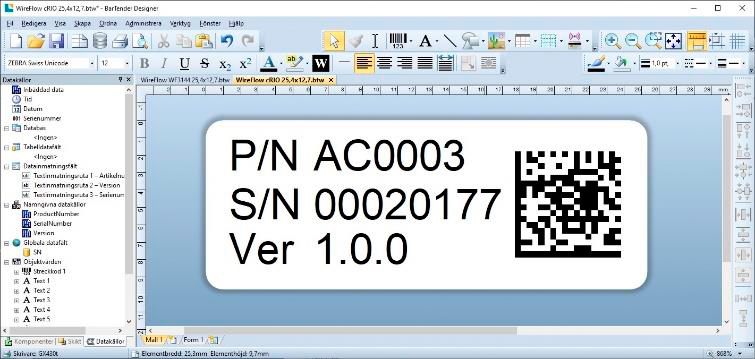

In conjunction with programming and testing of the circuit boards, it is common that the test station also generates labels which may be put on the boards and on any packaging. These labels can contain for example product number, version, and serial number.

The type of printer used depends upon the expected production volume and also whether the printer is used for multiple test stations or if each test station shall have its own dedicated printer. We have used printers from Zebra with good result. They are durable and work without disruption. We have the process in place to quickly integrate the Zebra printers into the WireFlow test stations.

For designing labels, we use the BarTender barcode labeling software from Seagull Scientific. It is the leading software tool for creating labels and barcodes. WireFlow has the skill and experience to design your labels for you. The tool integrates well with both the WireFlow test framework and the manufacturing planning database, and receives data for product id, serial numbers etc. from those systems.

BarTender, the barcode labeling software.

GX43t Desktop printer

ZT410 Industrial printer

Sheet of labels

Test station with computer, barcode scanner, fixture and label printer.

Barcode scanners

To streamline the work at the test station, it is usually a good idea to add a barcode scanner to identify the board to be tested. This information can be used by the test system to select the correct test sequence, software package for programming etc. The WireFlow test framework integrates well with most scanners on the market. We have had good experience using the Zebra scanners, for example the DS2200 series scanners.

Fingerprint login solutions

To simplify the login process to the test station, a fingerprint reader can be used. This is a convenient method for the operator, who just has to put their finger on the reader to login. It has been found that using this method increases the probability that the correct operator is actually logged in. For many operations, it is important to have traceability throughout the manufacturing and one such parameter is to know which operator was running the test station for a specific board. The login can also be used for user level restrictions, such as Operator, Technician or Administrator.

The WF 2111 can be used with the WireFlow Test Framework. An example of a manufacturer that uses fingerprint login is HMS Industrial Networks. They have successfully created a system where they can manage all user accounts from a central location. Their application is described in WireFlow’s Application note no 7.

Fingerprint login with the WF 2111 reader.

Touch screen interfaces

For the typical test station, we use an ordinary Windows PC with a screen for managing the station. For some stations it can be practical to use a touch screen as an operator interface instead of controlling it with mouse and keyboard. The graphical user interface for our test stations is designed to work well with touch screens as well. It is up to you to choose if you want to use a touch screen, or if you want to use traditional input devices like mouse and keyboard. The choice of solution will depend on whether the station is designed to make use of barcode scanners and fingerprint login devices.

Source controlsystem

When we design and configure your specific test station, we use a well-defined process to make sure all documents, drawings and software components are stored and version controlled in a safe place. For source version control we use Apache Subversion (SVN), and take daily backups of all data. We have long experience in configuration management, so you can feel safe in knowing your design files are in very good order, for any future needs.

Remote support tools

We assist you with the installation of the test system and support you at the production ramp up. It is common that a test system needs some tuning at the start of manufacturing to work flawlessly. Fine-tuning values for pass criteria is an example of such an activity. Once the system is in full operation, WireFlow can provide continuous support in case there is a need for updates due to new versions of the board or the software.

To enable remote support by our engineers, we install TeamViewer on the test computer. By using this tool, the WireFlow support team can do extensive trouble shooting and updating without travelling to your production site.

We provide support services on different levels depending on the required response time. We use a web-based support system where you can collaborate with our support team in the event of any problems. With access to the WATS test data our engineers can often very quickly pinpoint the root-cause to any problems.

Finally, our support team has a copy of the test system software running on a virtual machine in the WireFlow lab. This can be used to test upgrades etc. without requiring any access to the test station on the factory floor.

About WireFlow Test Framework

WireFlow has long experience in helping companies set up test and programming environments for electronic production. We have gathered all our tools and knowledge into a versatile framework we call WireFlow Test Framework. Using our framework, we can help you to quickly develop an effective and affordable solution for testing and programming your products in the production line.

Take a look at any of the other fundamentals of WireFlow Test Framework: