WF Bifrost Series

The WF Bifrost Series is a flexible and powerful battery test platform designed to support the entire battery value chain

Figure 1 – WF Bifrost Battery Tester

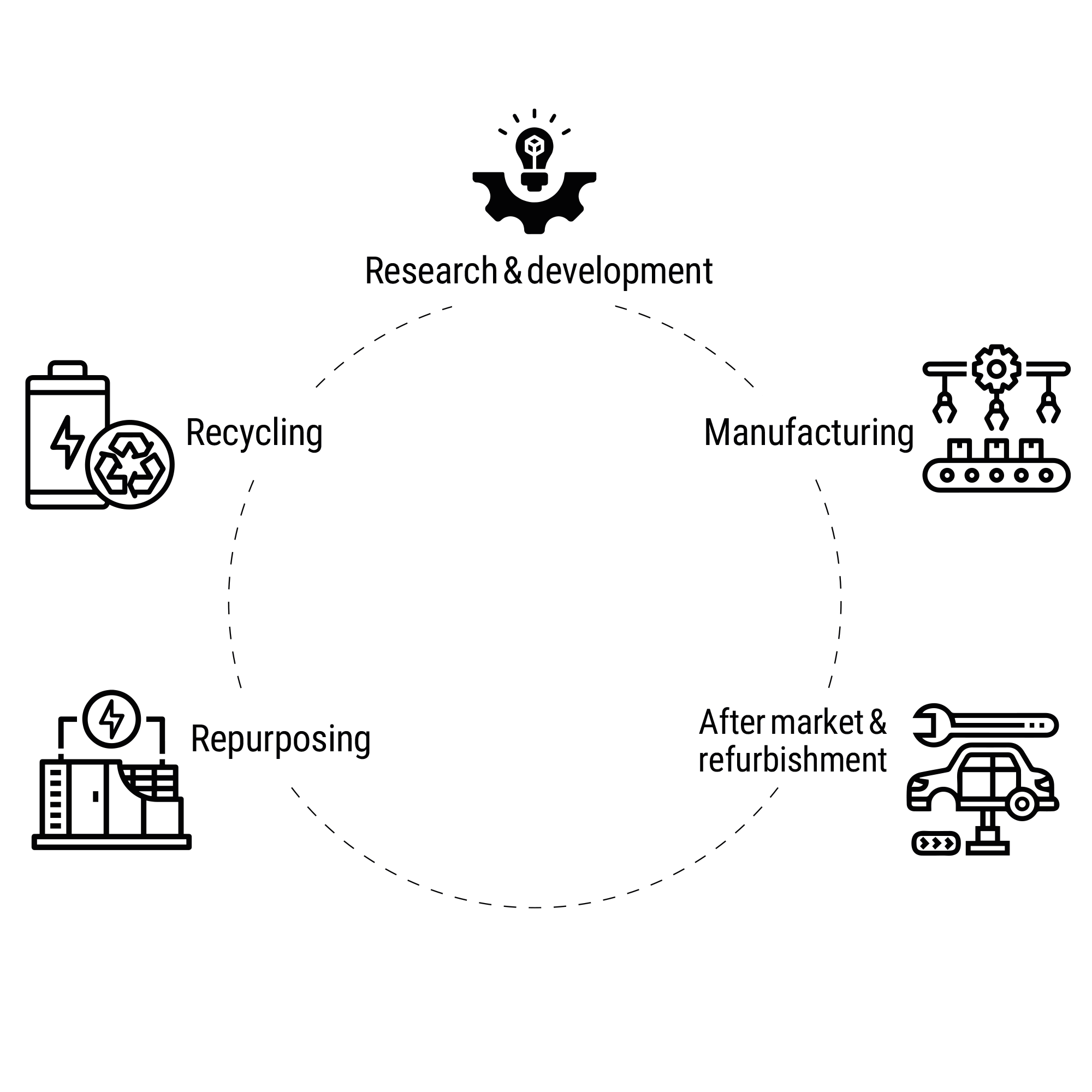

Built on WireFlow’s Valand Battery Test & Measurement Platform, Bifrost enables engineers and operators to safely test, charge, discharge, classify, and validate batteries throughout their lifecycle. From research and development to production testing, reuse, and recycling.

Each system is modular, configurable, and scriptable — combining hardware precision with software flexibility to deliver exceptional control, safety, and data traceability.

One platform – multiple applications for battery testing and lifecycle management

We offer both pre-configured solutions and customised systems with different functionalities to deliver a solution meeting your specific needs.

Research and Development

For labs developing new battery chemistries, modules, and packs, Bifrost provides complete test control and automation. Engineers can script and execute custom test scenarios for performance, endurance, and safety validation — accelerating innovation and data insight. Read more about battery testing for R&D.

Production and Quality Testing

On the factory floor, Bifrost systems deliver automated end-of-line testing and charging with high reliability. Each battery is identified, configured, tested, and charged to its target SOC — ensuring consistency, traceability, and readiness for shipment or integration. Read more about battery testing for battery manufacturing

Repair, Reuse and Refurbishment

In aftermarket and remanufacturing settings, Bifrost safely tests and classifies batteries for second-life use. The platform measures state-of-health, verifies communication, and ensures modules are fit for reuse before reassembly. Read more about battery reuse and recycling solutions.

Recycling and Energy Recovery

For batteries at the end of their service life, Bifrost supports controlled discharging and classification. The system ensures safe energy recovery and prepares batteries for dismantling or recycling — fully aligned with circular economy principles and EU Battery Regulation requirements. Read more about battery recycling solutions.

Figure 2 – Battery life cycle

WF Bifrost Series is powered by the Valand Platform for battery test automation

At the heart of every Bifrost system lies Valand, WireFlow’s adaptive and scalable software platform for test automation. It’s plug-in framework makes it simple to integrate new instruments, I/O modules, or measurement devices as research evolves. Hardware is automatically detected and ready to use.

Scripting and test automation

Engineers can create their own tests using Valand’s scripting language.

The built-in editor validates syntax and includes comprehensive help documentation.

All system variables are exposed within the scripting environment, allowing both simple and complex tests — from SOC or voltage cycling with coulomb counting to advanced fault-injection sequences for validating BMS logic.

Safety monitoring during battery testing

A background alarm system continuously monitors user-defined variables (for example voltage, current, temperature). If a limit is exceeded, Valand automatically places the DUT in a safe state.

Test data logging and traceability

All accessible data variables are logged during each test. Results are stored in uniquely named folders, easily exported or analyzed with external systems which ensures full traceability for both development and compliance reporting.

Centralized control

The system is controlled by a user-friendly software as a single point of contact. All stations can be run simultaneously and independent from each other and are controlled and monitored from one application.

System integration

Using our Rest API or Modbus-TCP, you can communicate and control the system from any adjacent system making it a seamless part of your production and test infrastructure.

Upgradable platform architecture

All products in this series are based on the Valand Battery Test and Measurement platform making it possible for customers to upgrade the systems with new versions and customer specific functionalities if needed.

Figure 3 – EV battery prepared for test

Downloads

WF Bifrost Series

AB0005-149 WF Bifrost Series.pdf

Battery discharging only?

Explore VoltDrain – WireFlow’s dedicated battery discharging container for safe and efficient discharge operations.

Contact WireFlow about Bifrost

Reach out to our team to learn more about the Bifrost platform and how it can support your battery testing and measurement processes.