Lundby Data Logger and Disturbance Recorder

The Lundby data logger is WireFlow’s standardized data logger system, based upon hardware from National Instruments (NI). Utilizing the NI world-class hardware platform, the Lundby data logger can offer a vast array of different types of acquisition modules. The Lundby logger system supports all NI hardware platforms, such as CompactRIO, CompactDAQ, PXI and FieldDAQ.

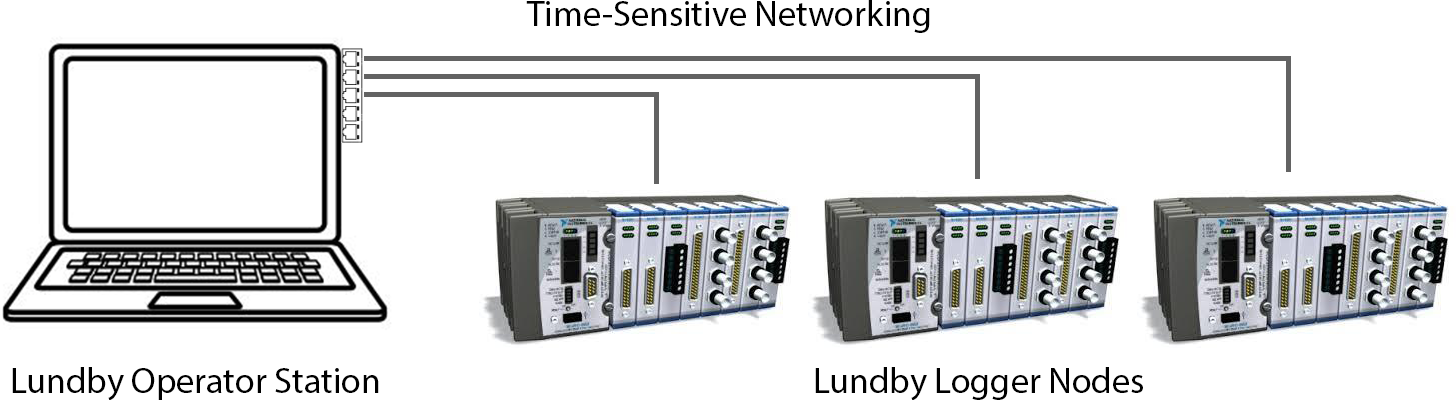

By networking these devices with a Time-Sensitive Network (TSN), Lundby logger becomes a time-synchronized system that can be scaled to thousands of channels and distributed over long distances using ethernet copper or fiber cables.

Quote request for Lundby Data Logger and Disturbance Recorder

Downloads & Information

Downloads

Brochure

Case Study

Specifications

– synchronization better than 1 microsecond with IEEE802.1AS

– Up to 1 MSample/s per channel.

– Cross triggering

– Supports NI PXI, CompactRIO, CompactDAQ and FieldDAQ

Features

– Easily distributed over large area using standard network cabling

– Supports local offline logging

– Designed for 24-7 operation

Application areas

– Large factory floors

– Structural measurements with data points far apart e.g. vibration and strain measurements on bridges, skyscrapers etc.

– Advanced aeronautical applications

– Off-shore wind farms

Introduction to the Lundy Data Logger: A Four-Part Video Series

Lundy Data Logger Introduction

Demo 1: Replacing a Node on a live system

Demo 2: Network disconnect while logging

Demo 3: Start logging while node is disconnected

WireFlow and NI Emerson | WEBINAR

About introducing Lundby: The Compact and Powerful Data logger

& Disturbance Recorder by WireFlow.

State-of-the-art logger system and Disturbance recorder

WireFlow Lundby Data Logger offers an ideal solution for large, synchronized logger systems. It supports real-time monitoring and recording of thousands of channels at high sample rates with a synchronization better than 1 microsecond. The Logger Nodes can be distributed easily over a large area using standard network cabling.

Besides acting as a classic data logger for ling time recording, Lundby can also react on disturbances by advanced triggering conditions and create super high speed recording during a disturbance with both pre- and post-triggering data.

Application

The need for highly synchronized monitoring and data analysis is increasing in many industries. Even a minor deviation of a few microseconds in data measured could lead to substantial analytical errors.

The Lundby Data Logger has been designed for applications logging very large amounts of high-speed, time-synchronized data with advanced cross-triggering capabilities. It supports multiple distributed Logger Nodes with up to 1 MSample/s per channel.

Lundby Data Logger supports local offline logging in individual Logger Nodes. This architecture makes it possible to record thousands of channels simultaneously at extremely high data rates when a trigger occurs. Another benefit of distributed autonomous nodes is that the system becomes very robust enabling a secure and redundant data logging process 24-7.

These features of the Lundby Data Logger make it the number one system for monitoring, disturbance root cause analysis, predictive maintenance modeling etc.

Typical applications are:

- Power plants

- Large factory floors

- Structural measurements with data points far apart e.g. vibration and strain measurements on bridges, skyscrapers etc.

- Advanced aeronautical applications

- Off-shore wind farms

Proven hardware platform

The Lundby Data logger is based on hardware from National Instruments (NI). Benefiting from NI’s world-class hardware platform, the Lundby Data logger offers a huge set of different types of data acquisition modules. It can use all NI hardware platforms such as CompactRIO, CompactDAQ, PXI and FieldDAQ.

By networking the data acquisition devices with a Time-Sensitive Network (TSN), Lundby logger becomes a time synchronized system that can be scaled to thousands of channels and distributed over long distances using standard ethernet copper or fiber cables.

Figure 1, TSN network with NI CompactRIO, CompactDAQ and FieldDAQ

Distributed to provide flexibility

The distributed design makes the system distance agnostic, providing synchronized high-speed data collection from different data sources kilometers away from each other. In addition to minimizing cabling requirements, it provides flexibility to add more Logger Nodes or change the topology if needed in the future.

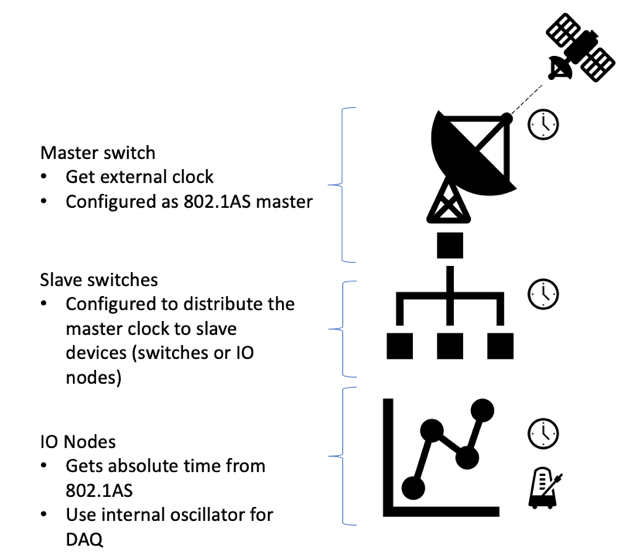

Synchronized to provide time accuracy

Further increasing the benefits of a distributed system, the Lundby Data Logger provides a high degree of time synchronization, better than a microsecond, between the different Logger Nodes. The master switch receives the absolute time from one or more clocks and the network synchronization standard IEEE802.1AS makes sure all nodes have the same absolute time.

Configurable to meet your specific needs

We understand that our customers’ data sources and topologies are diverse. No matter how many analogue, digital and vibration channels you need, our system is configurable to deliver a solution meeting your specific needs.

Scalable to meet your future needs

The flexibility provided by the distributed design makes the system easily scalable, with virtually no limitation to meet your future needs.

Redundant to maximize uptime

The distributed design provides redundancy in the complete solution. Each Logger Node executes separately, which enables the rest of the system to continue its operation even if one node stops working.

Local logging to maximize data throughput

Recorded data is continuously streamed to the centralized data storage at a certain data rate. The Logger Nodes can be configured to start sampling at a higher data rate for a limited time if something interesting were to occur. An automatic local storage function in the Logger Nodes balances the data throughput in the network to avoid network overload and possible data loss.

Technical Descriptions

System topology

A Lundby Logger Node is a highly configurable autonomous logger system that acquires data and stores it on a local disc with a high-resolution time stamp. It is synchronized with all other logger nodes via the Time-Sensitive Network (TSN). Data is transferred from the Logger Nodes to large discs in the operator station at regular intervals. Each Logger Node can be equipped with various number of I/O modules of different types.

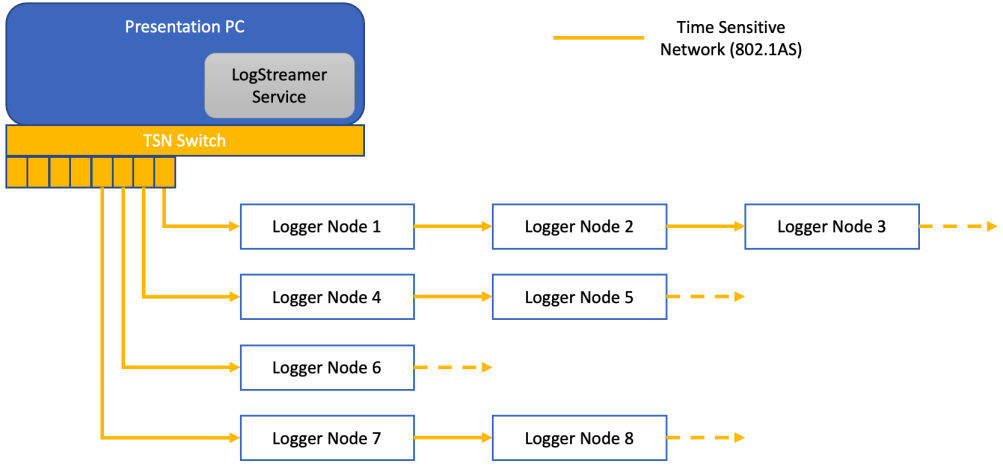

Figure 2. System Topology

The simplest topology uses a single small 8-slot Logger Node with a standard PC. The system can then be scaled up to hundreds of Logger Nodes with up to 16 modules for each node where each module can have various number of channels. One Logger Node could for example be configured with 16 modules of 32 analog input channels giving a 512-channel Logger Node. For longer distances, the Logger Nodes can be connected using optical fibers. They can also be daisy-chained for easy wiring.

Operator Station

The Lundby Operator Station is based on a standard Windows PC running the Lundby Operator Application. The operator station also includes a TSN switch to enable synchronization better than a microsecond between the Logger Nodes. For single node configurations the TSN switch can be omitted. The operator station can be equipped with large disc drives for logging almost arbitrary amounts of data.

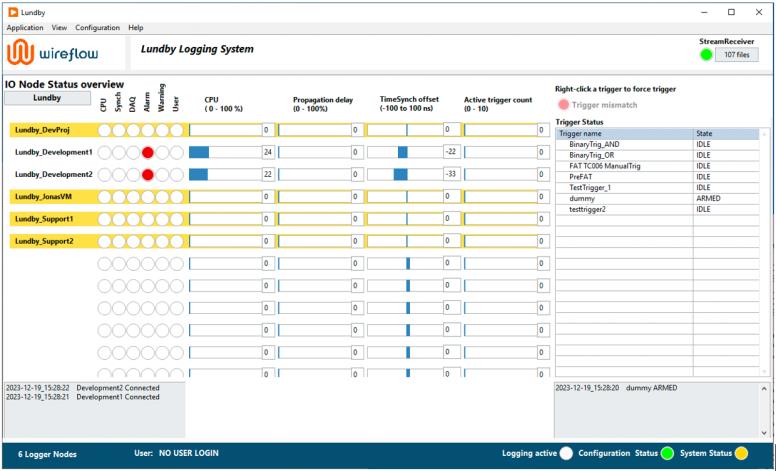

Figure 3. Lundby system status overview in the Operator Application

Logger Nodes

A Lundby Logger Node is an autonomous high-speed logger with a local disc and a configurable set of I/O modules making it possible to use hundreds of input channels for each node. The Logger Nodes can be configured with various types of chassis and different setup of I/O-modules. Furthermore, it is possible to add options such as daisy-chain interfaces, redundant power supplies etc. The Lundby Logger PXI I/O boards, CompactRIO C Series I/O modules or FieldDAQ devices are high performance measurement modules that connect to many types of sensors and support measurements such as temperature, voltage, resistance, torque, acceleration and more. The CompactRIO and FieldDAQ devices are designed to be rugged and portable with extreme industrial rating for hazardous environments.

Figure 4. The logger network can be a mix of star- and daisy-chain topologies

Functionality

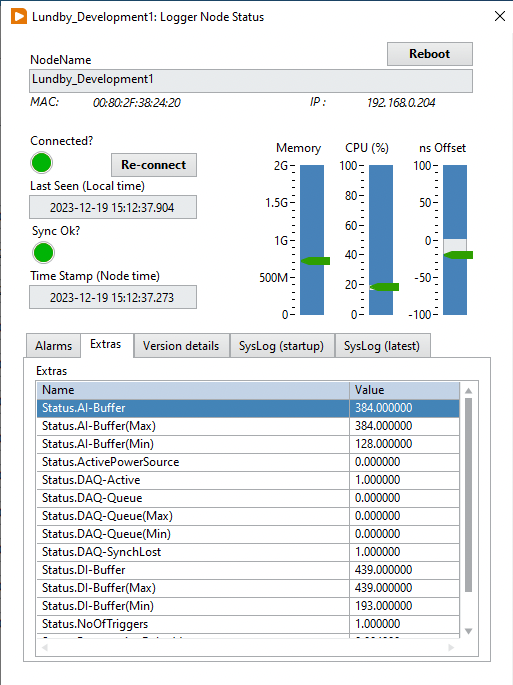

System Status Monitoring and Configuration

Lundby is built to be a robust system that can run 24-7 for years. It can for example be in stand-by mode for a long time and then when a trigger occurs, the system will be ready immediately to start recording at high speed. The Lundby system status monitoring functions make it possible for the operator to check that all nodes in the system are working and are ready to start recording when needed.

Each Logger Node continuously self-checks to ensure smooth operation. Any disturbances in the system are reported to the main operator PC.

Figure 5. Node status details

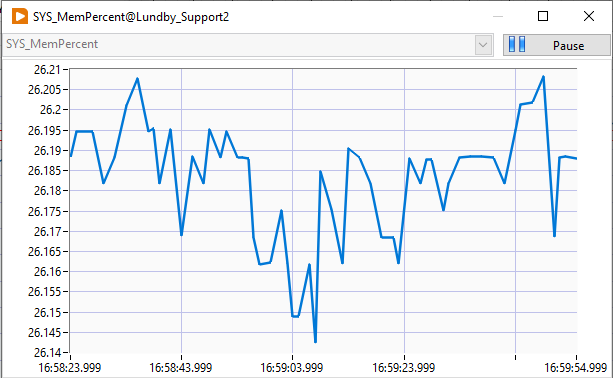

Besides monitoring the status of the Lundby system itself, it is also possible to monitor live measurement data from the distributed Logger Nodes.

Figure 6. Channel History window

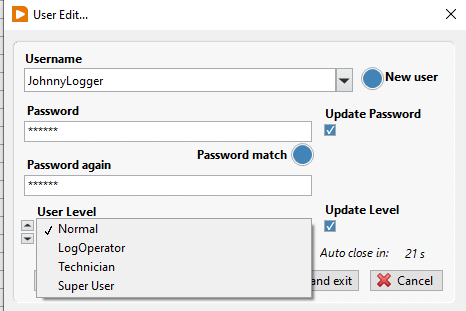

The system is setup and configured from the Operator Station. Unique users may access different functionality depending upon their access level.

Figure 7. User editing dialog.

Time Synchronization

The time synchronization feature of the Lundby Data Logger is the very core of the distributed data logging system. It relies on the clock being forwarded from a precise clock source over the network using the IEEE 802.1AS standard.

Figure 8. Time synchronization in Lundby

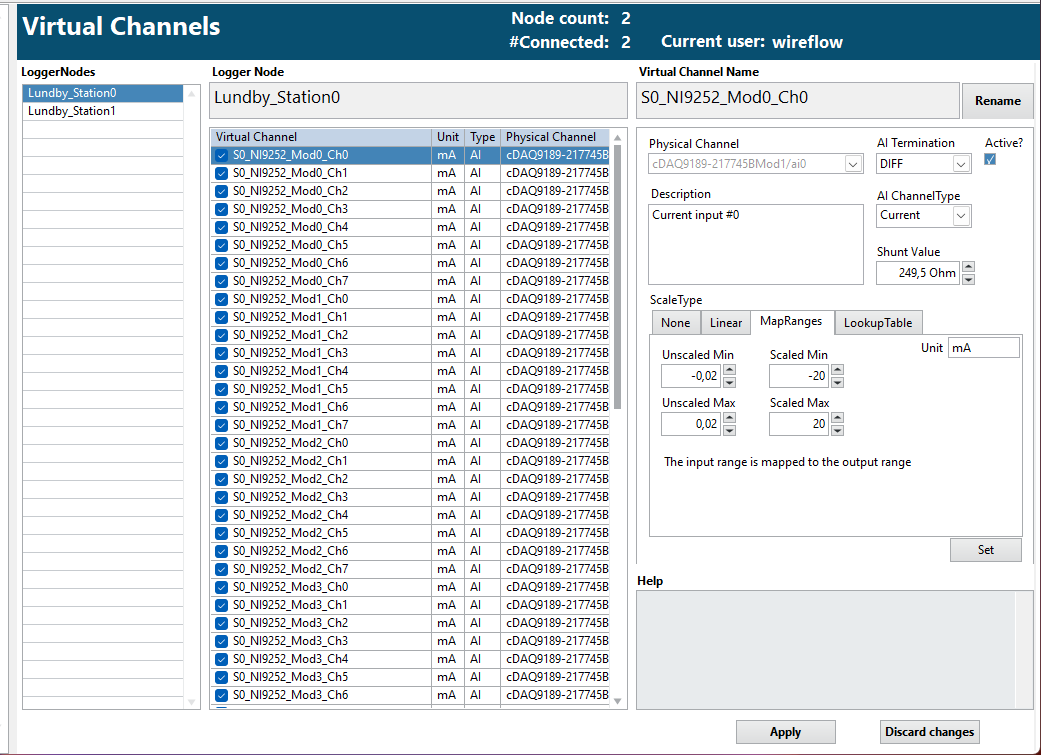

Virtual channels

Virtual channels are connected to a physical channel, converting the raw channel input to a physical value using scaling etc.

Figure 9. Virtual channel main view

Calculated channels

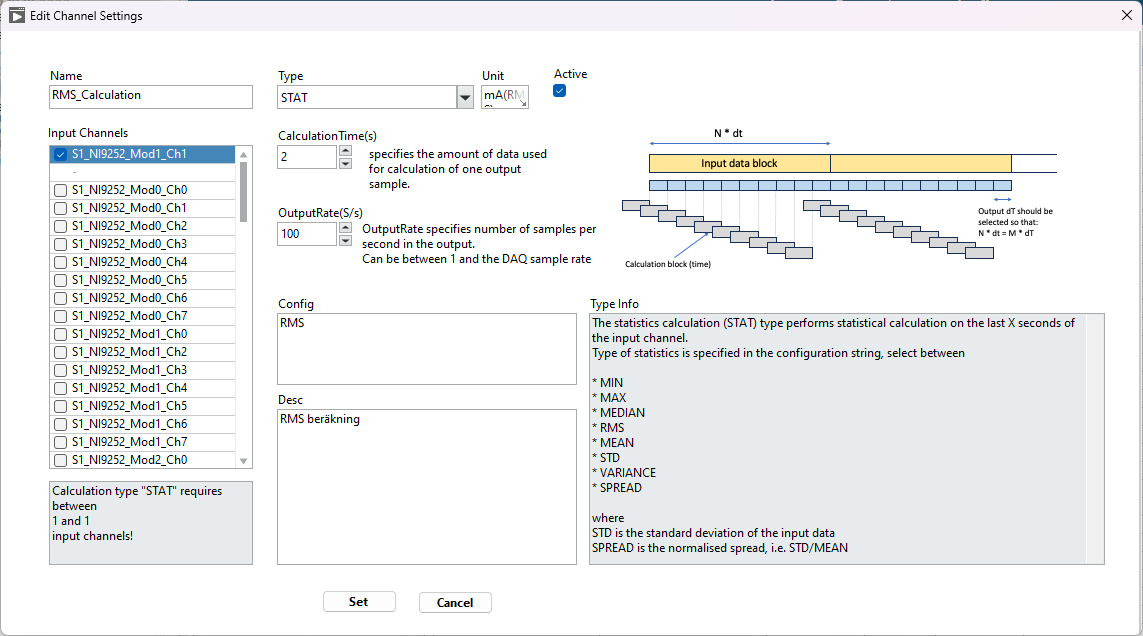

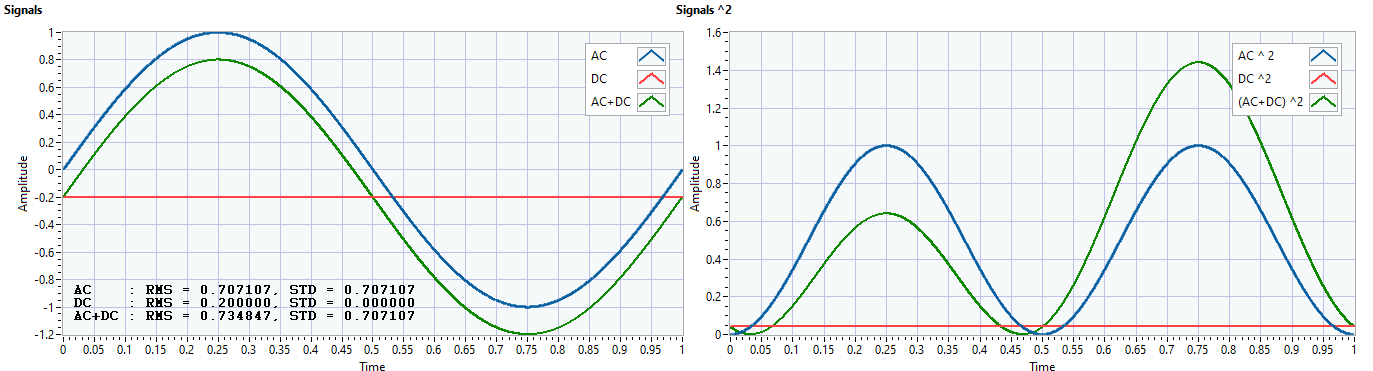

Calculated channels are intended to be used to get channel characteristics in real time, e.g. to define triggering conditions based on a channel characteristic like RMS or mean value.

Figure 10. Calculated channel editor

A typical calculated channel can be a True RMS calculation, meaning it considers both offset and waveform type.

Figure 11. RMS for AC, DC and combined

Continuous logging

The system supports continuous logging of data regardless of trigger states. Continuous data is limited to log data between 1 and 200 S/s and is most useful to monitor trends or calculated entities like RMS values.

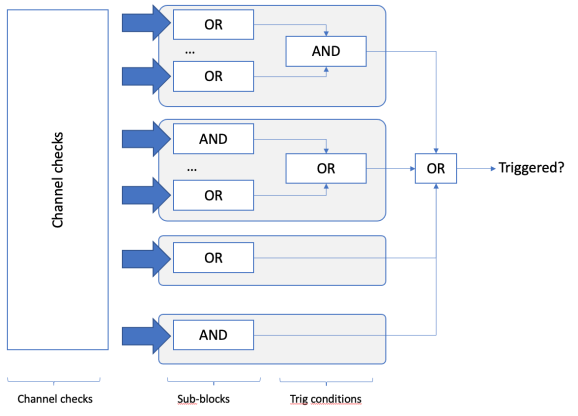

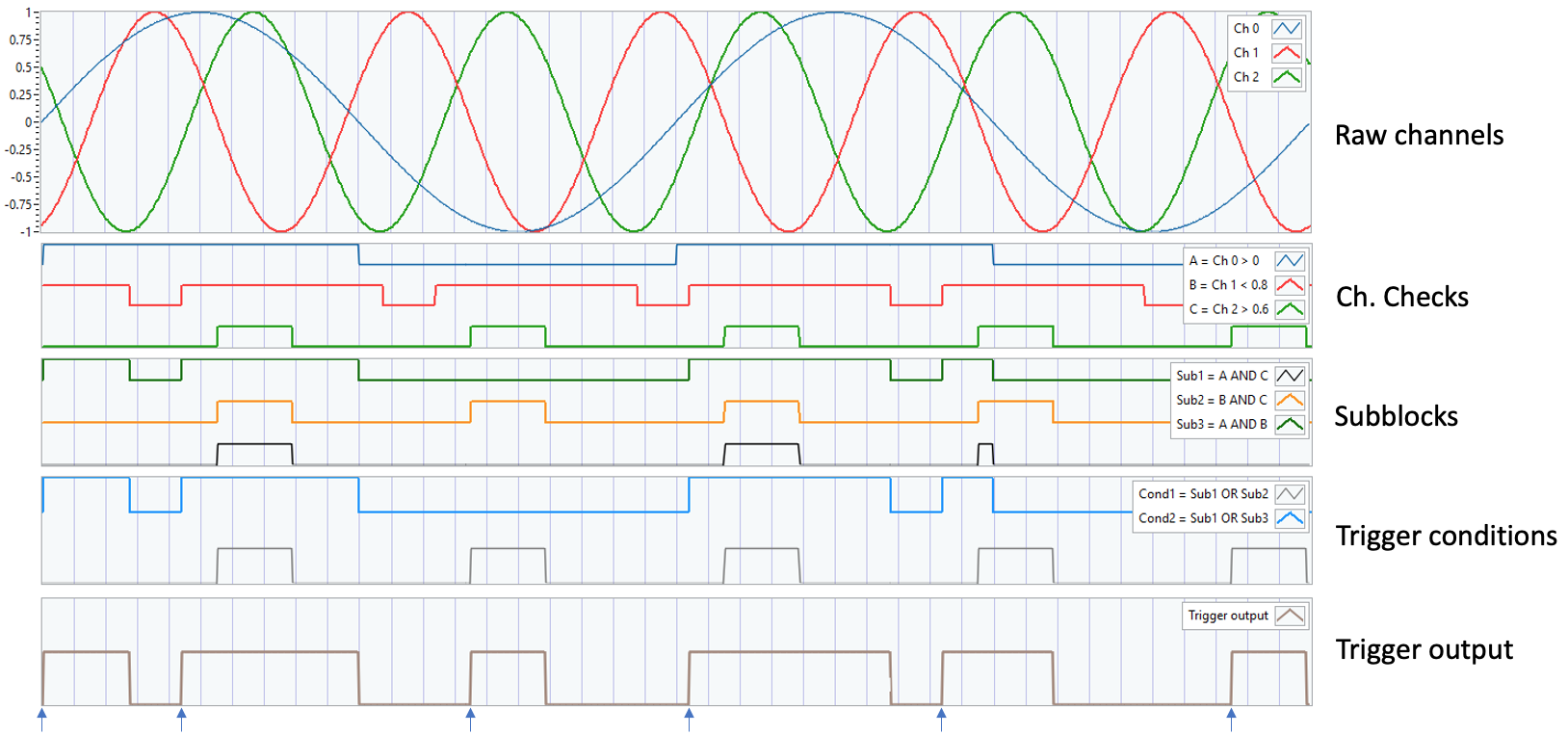

Triggers

Triggers are important functions used to only record data when something interesting happens in the system. Lundby provides several powerful and advanced trigger functions that are easy to use. One such function is the cross-triggering which can span over multiple Logger Nodes. This gives the user the ability to record data globally at a specific trigger condition.

A trigger condition can be based on a simple signal value as well as on a combination of Channel checks, i.e. checking that a channel enters a defined state.

Figure 12. Trigger evaluation

Figure 13. Trigger evaluation example

TDMS files

The data format for both Continuous logging as well as Triggered logging is TDMS. TDMS is a binary data format with META data. TDMS file format is developed by NI, and is described at:

https://www.ni.com/en/support/documentation/supplemental/06/the-ni-tdms-file-format.html

The benefit of TDMS is the ability to add META data to individual channels, channelgroups or the file itself, meaning that system properties, channel properties as well as trigger properties can be written to file.

There are plugins for various applications to enable them reading the TDMS file format, e.g. Excel and MatLab.

For performance reasons, the data is written as Waveforms. Thus, instead of creating and writing sample timestamps, data is written with properties on the channel defining the timing and the sample interval.

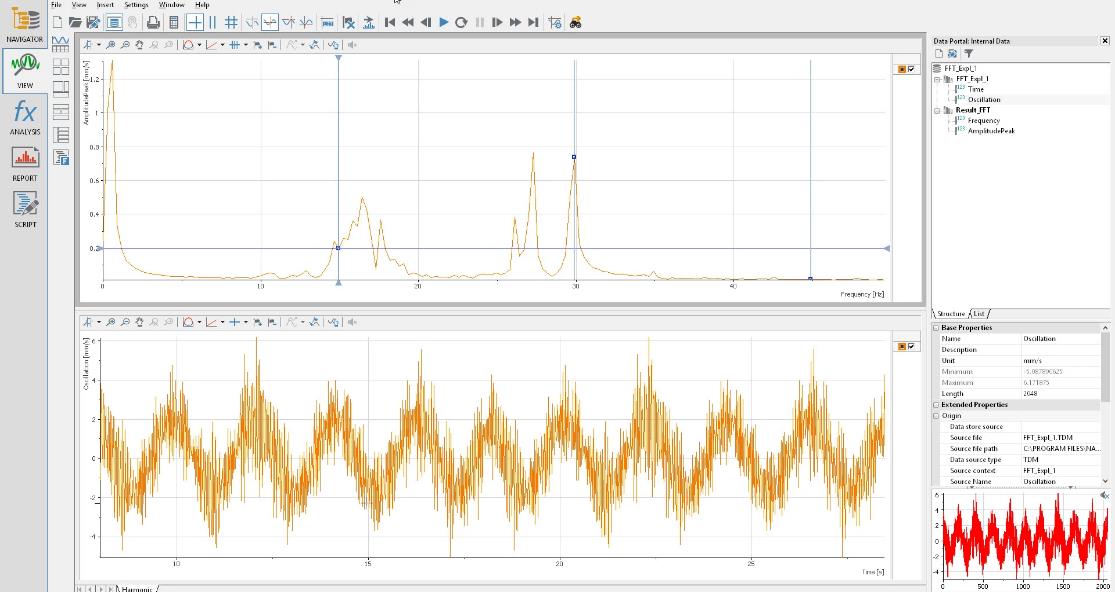

Data analysis

The Lundby Operator Application includes live data measurement presentation in both table and graph format. For more advanced data analysis, the NI DIAdem Software can be integrated with the Lundby logger. DIAdem is the perfect tool to process, visualize, and streamline root-cause determination on the data recorded with the Lundby logger. With Lundby and DIAdem you can minimize time spent on repetitive tasks by automating steps like transforming data into insights through analysis and generating reports with standardized templates.

Figure 14. Interactively view data from different channels using DIAdem

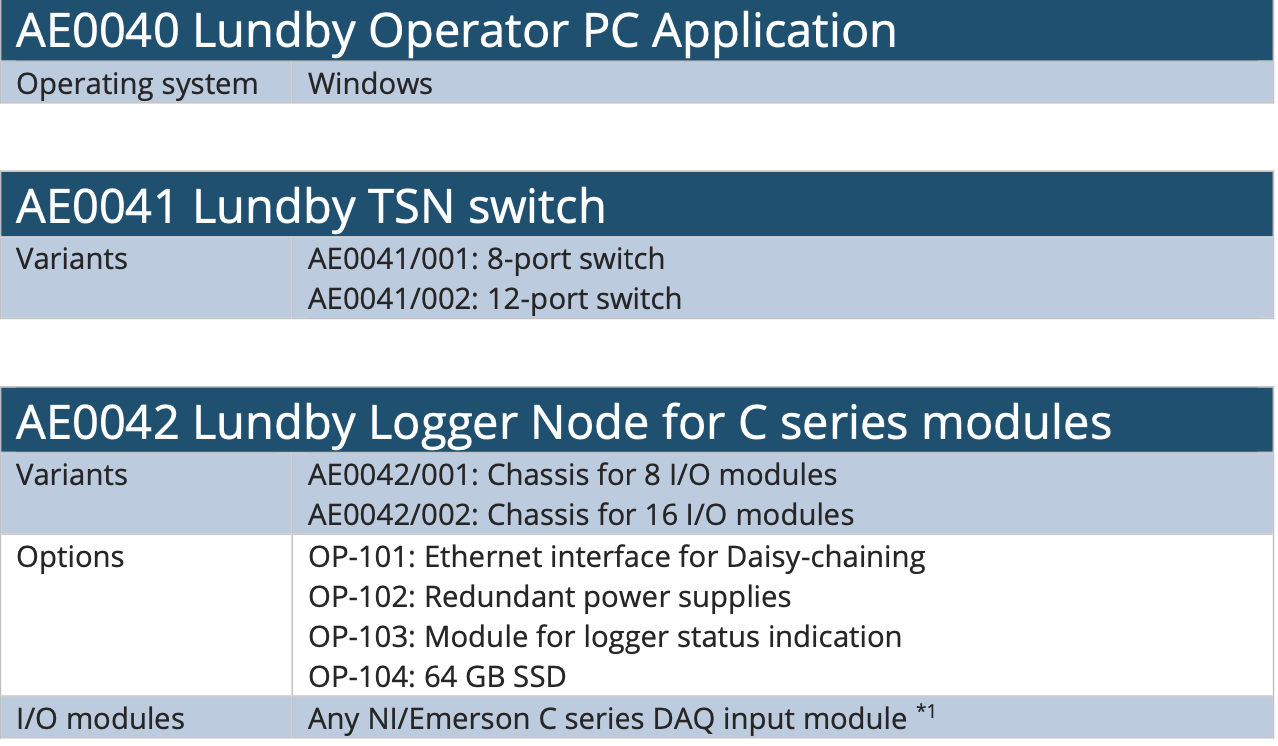

Ordering information

*1 C Series CompactDAQ modules connect to many sensors and buses and support measurements such as temperature, voltage, resistance, audio frequency, strain, pressure, load, vibration and more. For more information on the module product range visit:

https://www.ni.com/en/shop/compactdaq/compactdaq-modules.html

* Please call for interest in Lundby Logger Nodes for PXI or FieldDAQ.